Simon Beer of Calibso considers the benefits of acoustic windows and doors, sharing his experience of them being installed.

A typical urban housing estate will be subject to a wide variety of external sound sources, including planes, cars, lawnmowers, motorbikes and scooters and barking dogs – the list is seemingly endless. Whether sound is a nuisance really depends on the person who is hearing it, and when they hear it. For example, the person who constantly whistles their way around the garden might think that they are making a tuneful noise, but the neighbour who is trying to work inside might have other ideas. Or what about the noise from the lawnmower, circular saw, or party at a time when you were hoping to sleep? Modern housing policy requires people to live closer together. If you want to have easy access to travel, you will need to be situated close to transportation networks, which means that you will have flight paths, train lines and roads nearby. Couple that with the drive to use brownfield sites where possible, and the density of people occupying a space is dramatically increased.

Sleep disturbance

Then you have the 24-hour society. People come and go at all times of the night, with many shops and clubs staying open through the night to cater for them. It isn’t unusual for someone to leave their house at 3 or 4 in the morning. If this happens in the winter they will probably leave their car running for several minutes while scraping frost off the windows, causing sleep disturbance for others. Even the countryside is not immune to noise disturbance. Towards the end of the summer, you are likely to be kept awake by farmers using machinery through the night, so that they can reap the harvest in time. Roughly ½ million complaints are made to the council about noise every year, with less than 1% resulting in action being taken. That means that more than 99% of people who are sufficiently bothered by noise to complain about it have to carry on living with it, possibly with an acrimonious relationship with their neighbours as a result of the complaint. Complaints to the council are recorded, so when you come to sell your property, you will need to declare that you have had a dispute with your neighbours, which could cause problems with the sale of your house.

Excessive exposure

The potential impacts of excessive exposure to noise are well documented. It can cause a number of medical problems including depression, stress, high blood pressure, sleep deprivation, birth defects, low birth weight, stomach ulcers and changes to the immune system. Hearing gradually degrades as a result of old age, but this degradation is accelerated when you are constantly exposed to a noisy environment. Noise levels that can cause sleep disturbance are relatively low (around 40 dB) and sleep deprivation over a prolonged period can also cause problems. For example, sleep-deprived people tested by using driving simulators or hand- eye coordination tasks have been found to perform as badly as or even worse than those who are intoxicated. Prolonged sleep deprivation is also said to increase the risk of heart disease and stroke.

Taking action

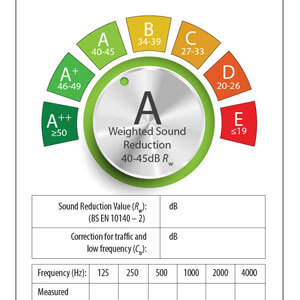

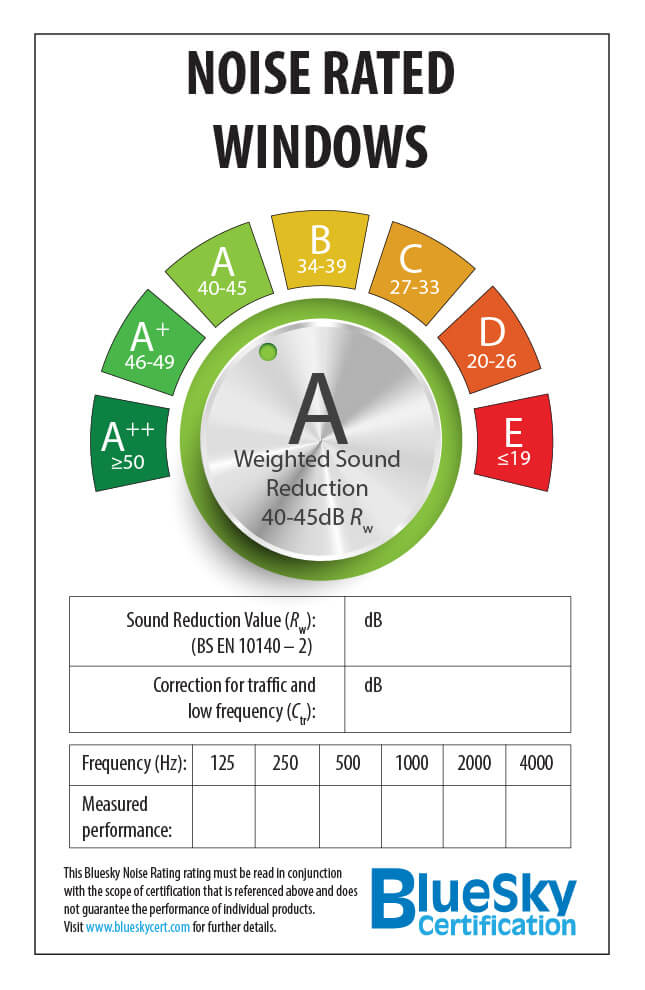

So what can action can someone take if they are regularly disturbed by external noise in their home? Moving house is a drastic step, which will cost a substantial amount of money and won’t even guarantee quiet. I have a friend who lives in a house at the end of a seemingly quiet country lane, surrounded by fields, but has to listen to his neighbour’s dogs continually barking through most of the day and night. You can’t change the location of your house, or in most instances what is happening around it, but it is possible to reduce the amount of noise coming into the building from the outside. Living under a flight path close to Heathrow, I am well aware of the impact that external noise can have, particularly on sleep. My road is used as a rat run during the rush hour, and occasionally as an illegal race track in the middle of the night. I like where I live, but on occasion, it would be nice to block out the external noise. Having been heavily involved in developing services relating to acoustic windows, I have often wondered what the impact of installing acoustic windows would be. So when one of my neighbours was recently choosing replacement windows, I suggested that he consider an acoustic window, and gave him details of a product that has been proven to achieve a weighted sound reduction of just over 40dB. The additional cost was not significant, so he took my advice and ordered the acoustic specification.

A little concerned

Before the installation took place, I have to admit that I was a little concerned. I had persuaded my neighbour to spend more than he would have based on what I had seen in a test lab, without having any practical experience of what the affect would be. Fortunately, my neighbour was extremely pleased with the result, and was keen for me to see, or rather hear the difference. Inside his front room, you can see the cars going past and planes going over the house, but they are now almost completely unheard. Sounds from inside the house are now prominent. The Sky box periodically makes a virtually imperceptible tick and you become aware that the compressor on the fridge is occasionally starting up in the other room. There is no doubt that the acoustic windows have dramatically reduced the noise levels in his home, so much so that another neighbour has now upgraded his windows and followed suit with the same specification. I would suggest that any manufacturer considering offering an acoustic window or doorset should have the performance of their complete product tested. The specification of glass fitted to the product will have a huge effect on its acoustic performance. However, my experience is that the glass is only part of the equation, with the profiles, seals, ventilators and other components all playing vital a part in the overall performance. How they are fitted is also important. Elimination of any air gaps and proper compression of the seals is crucial. I have seen different windows or doorsets fitted with a similar specification of glass having a variation in performance of up to 10 dB. In some tests, the performance of complete window or doorset can actually be better than that of the glass itself.

Completely eliminated

Companies who are considering offering acoustic products have often expressed concern about what the householder might say if noise from outside the building is not completely eliminated. In the same way that the glass is only part of the story with relation to the performance of the complete door or window, there are other areas in the building that will allow the passage of sound. You therefore need to include caveats at the time of the sale, stating that sound will be transmitted through other parts of the building. Examples include airbricks, loft insulation and gaps around pipework, all of which can be dealt with. A common issue with houses from the 1970s is that the walls often include a system whereby tiles are fixed over the top of a timber stud, often with no insulation in between. Details like this will not only affect acoustic performance though, the heat loss through that area will also be significant. If you are concerned about the householder complaining that the noise is still there, you should probably mention these areas as a potential source of heat loss when selling energy efficient products.

Very attractive

Some people may not consider replacing their windows just to cut out the noise, but if they are replacing windows or doorsets already, the additional cost of a product that performs better in reducing the amount of noise that comes into the building may be very attractive. It would be considerably cheaper to improve the specification at the time of ordering, than to retrospectively upgrade the windows at a later stage. You could therefore upsell your noise reducing product, to earn extra income at the time of the sale. Alternatively, you don’t have to look too hard to find houses on a busy road, under a flight path, near a train line, or in another location that is affected by noise – maybe the noise reducing capability of your products could be the argument that persuades someone to buy? Everyone is now selling energy efficient windows and doors, and even the minimum specification required for building regulations compliance is pretty high. If you are looking for the next unique selling point, maybe you should consider acoustic performance?

This article is also published at windows active.

An Englishman’s home is his castle is a phrase that has been around for centuries. It means that English people believe that they should be able to control what happens in their own homes, and that no one else should tell them what to do there. Nowadays we have the ability to control much of what happens in our own homes from our smart phones, with apps available to control central heating, lighting, hot water, entertainment systems, security systems etc. But if someone starts making a racket outside, or your house happens to be near a busy road or under a flight path, are the only options really to either put up with the noise or move?

An Englishman’s home is his castle is a phrase that has been around for centuries. It means that English people believe that they should be able to control what happens in their own homes, and that no one else should tell them what to do there. Nowadays we have the ability to control much of what happens in our own homes from our smart phones, with apps available to control central heating, lighting, hot water, entertainment systems, security systems etc. But if someone starts making a racket outside, or your house happens to be near a busy road or under a flight path, are the only options really to either put up with the noise or move?