Over recent years, the awareness of various important safety aspects of window and door installations has increased. It is now unlikely that an installer would be unaware of the requirement to fit safety glass in low level glazing, however, there are some important fire safety aspects that can easily be overlooked when replacing doors and windows, both for commercial and domestic situations. When speaking to installers, I often find that knowledge in this area could be improved.

Examples of some key areas that need to be considered are as follows:

Fire spread in cavity walls:

Removal of a timber window or door and replacement with a PVCU product may inadvertently increase the building’s fire risk. Installers are usually aware that a timber window can provide structural support, but what is often not appreciated is that it can also act as a barrier to prevent fire from entering the cavity wall. If fire enters a cavity wall, it can spread to other parts of the property, or in the case of terraced houses, other neighbouring properties. In order to prevent fire spread, the Building Regulations requires fire resistant cavity barriers to be fitted to all openings in the cavity. Various materials including steel or timber may be placed over the cavity to provide this function, but PVCU (with the exception of specifically tested products) is not one of those materials. A timber window or door that closes the cavity should therefore not be replaced with a PVCU product unless an insulating fire resistant cavity closer is fitted to close the cavity.

Installation of fire resistant doorsets:

To achieve fire resistance performance, the doorset is tested in a furnace at flashover fire temperatures (roughly 950 degrees Celsius) and must contain the fire for the duration of the declared performance (e.g. 30 minutes for an FD30 doorset). This is a particularly onerous test and it is impressive to see a product that passes. Once the test is complete, the specification of the product that was tested must be replicated in the manufactured doorset, with any variations being covered by an assessment report.

In order to retain its fire resistant performance, a fire resistant doorset will need to need to be installed differently to that of a normal door. For example, the void between the frame and surrounding brickwork will need to be backfilled with a non-combustible material that is capable of the required fire resistance in the configuration in which it is being used (e.g. mineral fibre and / orintumescent mastic) and the door gaps of less than 4mm will usually be required. The doorset manufacturer should provide instructions for fitting, or if they are not available, BS8214 or other relevant industry accepted standards should be used to ensure that the fire resistant performance is retained.

Having worked for a fire test laboratory, I am well aware that common installation defects can reduce the performance of a 30 or 60 minute doorset to as little as 7 or 8 minutes, effectively turning the fire doorset into a standard doorset and removing the fire protection. I would therefore advise that installers of fire resistant products are specifically trained for this, or preferably 3rd party certified.

Specification of fire resistant doorsets that also need PAS 24 security performance:

Where an external doorset requires both fire resistance and security performance, it is important that the specification of the doorset supplied meets both criteria. The test standards for fire and security are different, and it can be difficult for a manufacturer to achieve both on the same doorset. If the specification of a fire resistant doorset is modified to achieve the security performance, it is likely that the resulting product may not pass either test. Therefore, when purchasing such a product, the manufacturer’s scope of certification should be checked to confirm that the product supplied meets both criteria. If you are supplying to a Secured by Design site and haven’t confirmed this, as well as having a product that may not perform as inspected, the product is likely to be rejected.

Buildings in close proximity and windows / doors near fire escapes:

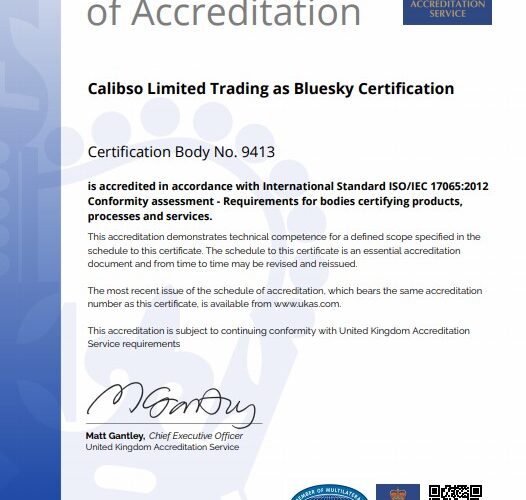

Finally, when a window or doorset is being replaced on the face of a building that is in close proximity to another building or near to an external fire escape staircase, the Building Regulations should be checked as it may be that a fire resistant doorset or window should be fitted. Fire resistant doorsets or windows should be proven through test evidence for the whole doorset / window from a UKAS accredited laboratory, and windows should also be non-opening.

Company overview for Calibso:

Calibso provides a wide range of support services to the fenestration and fire resistant industries, including project management, assistance with development of new services, inspection and auditing services. For more details visit www.calibso.co.uk or contact us via enquiries@calibso.co.uk or 01753 303828.

This article was originally published in windows active in August 2016